COMPRESSED AIR SYSTEM

- Compressors

- Air Receivers

- Air Filters

- Dryers

- Oil-Water Separators

- Condensate Drains

- Controls

- Compressed Air Quality

- Energy Management in Compressed Air System

COMPRESSORS

- Screw Compressors

- Piston Compressors

- Scroll Compressors

- Turbo Compressors

- Oil-Lubricated and Oil-Free

- Heat Recovery System for Energy Savings

AIR RECIEVERS

- Volumes Ranges: 50L, 60L,90L, 160L,250L, 270L,350L, 500L, 750L, 1000L, 1,500L, 2,000L, 3,000L, 5,000L and 10,000L.

- Pressure Ranges: 11Bar, 16Bar, 36Bar and 41Bar.

AIR FILTERS

- Cyclone or Water Separators

- Pre-filters

- Micro-filters

- High Pressure Filters

- Activated Carbon Filters

- Sterile Filters

DRYERS

- Refrigerant Dryers

- Adsorption Dryers

- Active Carbon Absorber for oil free compressed air

- Adsorption Dryers for breathing air

- High Pressure Dryers

OIL-WATER SEPERATORS

The ’Condensate Cleaner ‘condensate treatment system gives compressor operators an easy way of treating compressed air without external assistance.

CONDENSATE DRAINS

- Mechanical no loss drains

- Timed controlled drains

- Electronic no loss drains

CONTROLS

- Airtelligence trinity, Controls up to 3 compressors.

- Airtelligence plus, Controls up to 6 compressors.

- Airtelligenceprovis 2.0, Controls up to 16 compressors and up to 24 accessory components.

- BOGE connect, Remote monitoring.

- Intelligent machine control systems.

COMPRESSED AIR QUALITY – MEDICAL COMPRESSED AIR

Boge supplies medical compressed air system with minimum triple-redundant design for compressed air generation. With BOGE treatment units the compressed air generated undergoes drying, cleaning and processing in eight stages to deliver medical compressed air complying with DIN EN ISO 7396-1 and ensure top-quality respiratory air, whether supplied for artificial respiration or destined for anesthesia systems.

COMPRESSED AIR QUALITY – OIL FREE COMPRESSED AIR

- Boge offers a variety of oil-free products like:

- Boge BLUEKAT Screw Compressors

- Boge Scroll Compressors

- Boge PO Piston Compressors

- Boge SO Screw Compressors

- BOGE offers an extensive range for the preparation of compressed air, specially for oil-lubricated screw compressors: Measures for drying and filtering as well as the use of activated carbon ensure reliable oil-free compressed air. If another BLUEKAT converter is added downstream, you still obtain class 0 compressed air. With “FoodLub-H1” there is also a special lubricant that is officially approved for sporadic contact with food.

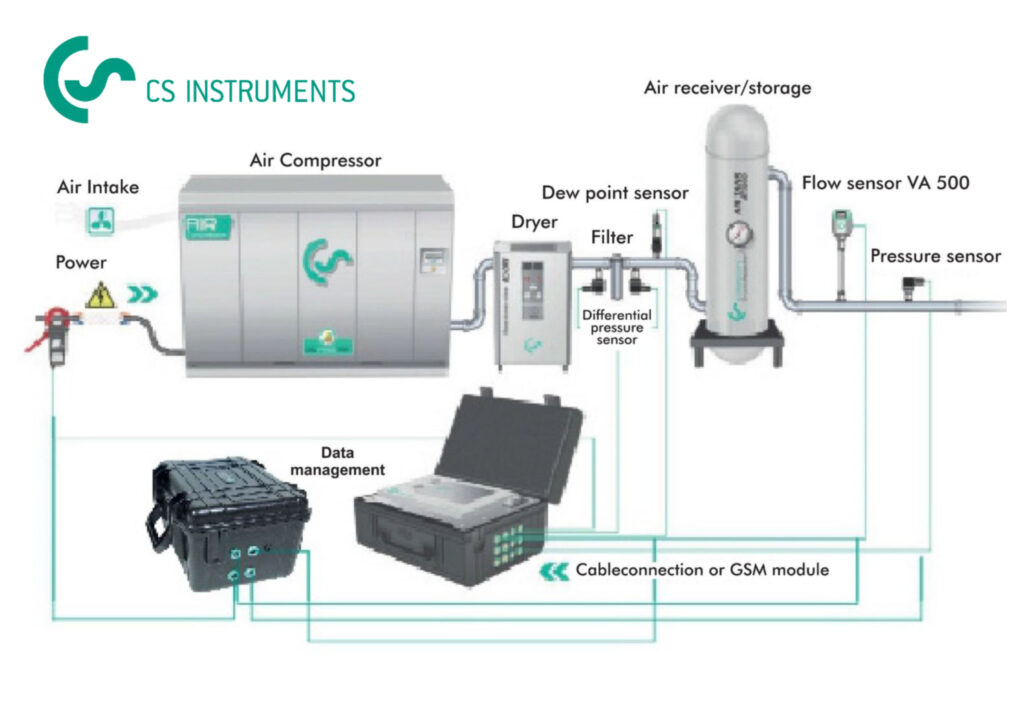

COMPRESSED AIR QUALITY MEASUREMENT ACCORDING TO ISO 8573

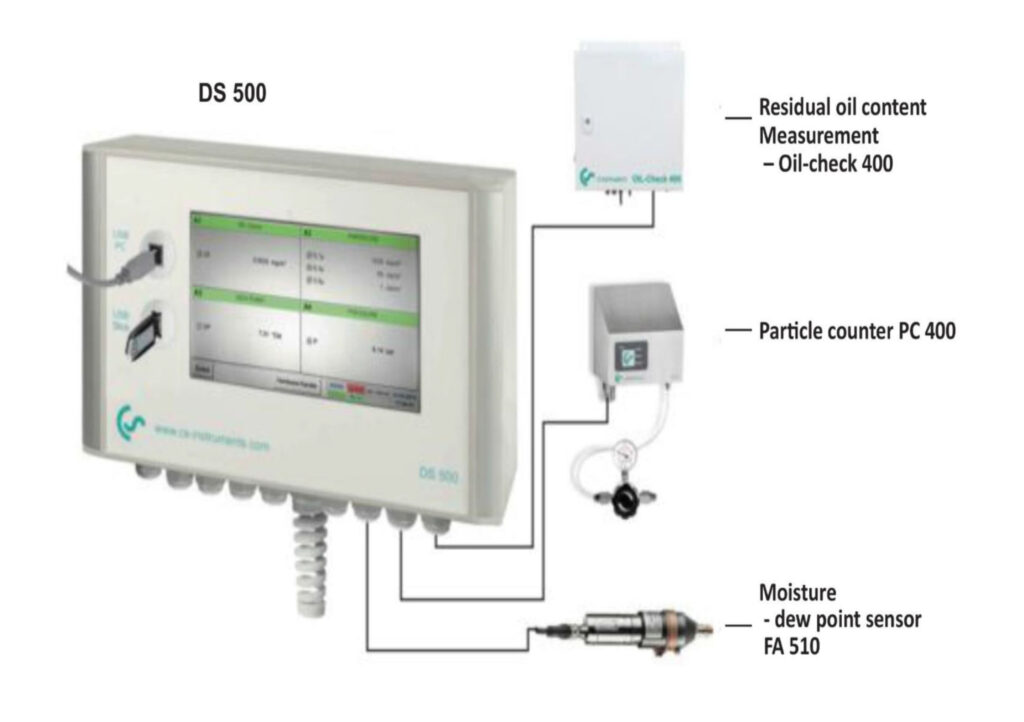

CS Instruments offers three customized solutions for stationary and mobile monitoring. An alarm can be used to signal that maintenance work is required on the compressed air treatment system (dryer and filter) so that oil, water and particles do not enter the compressed air network. This reduces and prevents the risk of contamination of end products and increases the process reliability and lifespan of pneumatic components.

- The residual oil content sensor OIL- check 400 measures the vaporous residual oil content in the compressed air according to ISO 8573.

- The highly precise optical Particle Counter PC 400 measures particles from a size of 0.1 µm and is therefore suitable for monitoring of the compressed air quality class 1 ISO 8573.

- Moisture measurement with FA 510 Dew Point Sensor.

- DS 500 – Intelligent Chart Recorder + CS Basic – data evaluation in graphic and table form.

ENERGY MANAGEMENT IN COMPRESSED AIR SYSTEM

- Monitoring of compressed air consumption and energy cost

- Monitoring of compressed air leakages and losses

- Implementation of monitoring analysis and results

- Continuous monitoring of compressed air optimizations