COMPRESSED AIR & GAS INSTRUMENTATION

Measurements and Controls for the Compressed Air & Gas Industry

- Dewpoint Measurement

- Flow Measurement

- Leak Detection

- Pressure Measurement

- Compressed Air Quality Measurement

- Recorders

- Software

- Power Meters

DEWPOINT MEASUREMENT

- SUITABLE APPLICATIONS:

- Air / Compressed Air

- Carbon Dioxide (CO2)

- Methane (CH4)

- Nitrogen (N2)

- Oxygen (O2)

- Natural Gas

- Argon (Ar)

- Hydrogen (H2)

- Other gases on demand

- PRODUCTS:

- Field Mountable Dewpoint Sensors

- Field Mountable Dewpoint Sensors in Combination with Field Mountable Recorders and Indicators

- Mobile and Portable Dewpoint Meters

FLOW MEASUREMENT

- SUITABLE APPLICATIONS:

- Air / Compressed Air

- Carbon Dioxide (CO2)

- Laughing gas (N2O)

- Nitrogen (N2)

- Oxygen (O2)

- Propane (C3H8)

- Argon (Ar)

- Hydrogen (H2)

- Natural gas

- Helium (He)

- Methane (CH4)

- Vacuum

- PRODUCTS:

- Compact Inline Flow Meters: Flow sensor with integrated flow straightener / no inlet sections necessary.

- Insertion Flow Meters

- Inline Flow Meters: Flowmeter with integrated measuring section.

- M-Bus – Industrial gas meter

- Insertion Flow Meters in Combination with Recorders

- Vortex Flow Meters for mixed gases and corrosive media applications

- Vortex Ultrasonic Flow Meters for technical and mixed gases applications

LEAK DETECTION

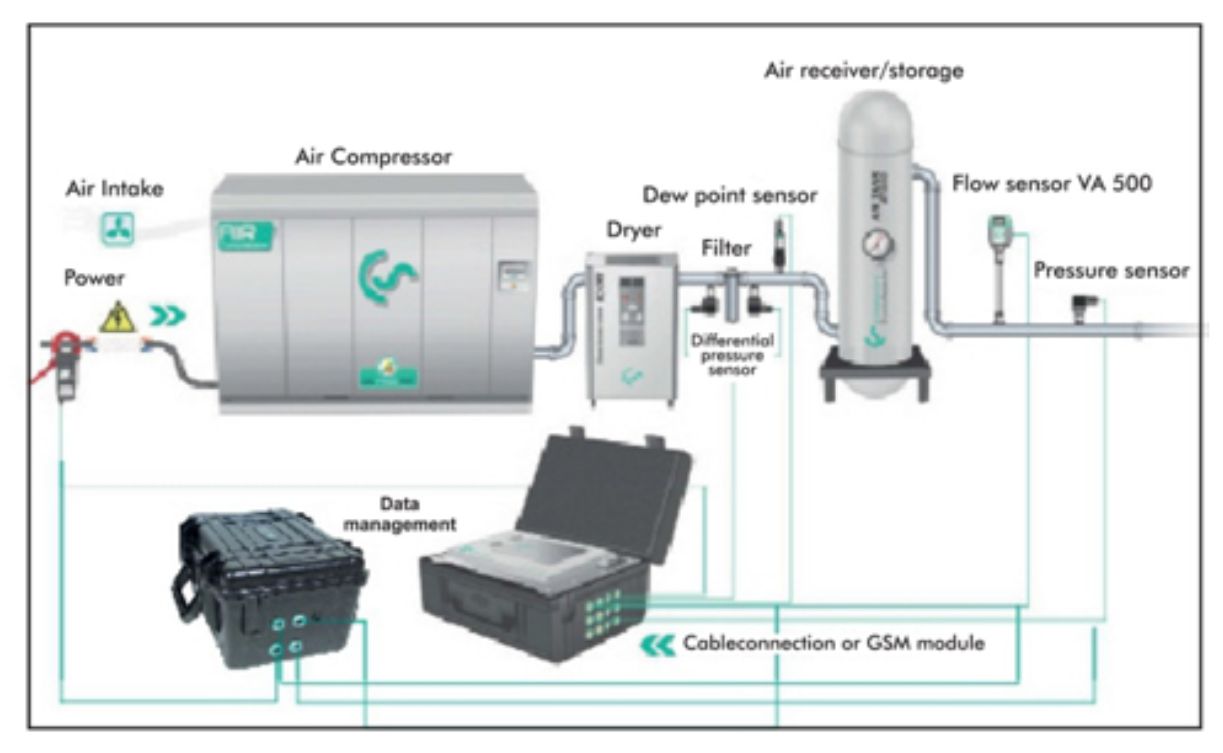

Typical applications of our measuring instruments in this section are leakage detection in compressed air systems and leak testing of unpressurized systems.

- Leak detector with camera LD 500/510: indicates leakage rate in l/min and costs in €.

- CS Leak Reporter software for leak detector LD 500/510: Easy leak reports according ISO 50001

- Leak detector LD 400: By means of the LD 400 even the smallest leakages in compressed air lines, gas, vapor, vacuum plants or refrigeration plants can be detected even from distances of several meters.

PRESSURE MEASUREMENT

Pressure monitoring in compressed air and gas systems helps to significantly reduce energy consumption.

- Mechanical Pressure Gauges

- Standard Pressure Sensors. Ranges: 10 bar, 16 bar, 40 bar, 1,6 bar absolute, 100 bar, 250 bar and 400 bar.

- Differential Pressure Sensor to test filter performance.

COMPRESSED AIR QUALITY MEASUREMENT – Residual Oil Content Measurement OILCHECK according to ISO 8573.

The residual oil content sensor OIL check measures the vaporous residual oil content in the compressed air.

- Stationary Solution in combination with the DS 400 (Recorder).

COMPRESSED AIR QUALITY MEASUREMENT – Particle Counter PC 400 according to ISO 8573.

The highly precise optical particle counter PC 400 measures particles from a size of 0.1 µm and is therefore suitable for monitoring of the compressed air quality class 1 (ISO 8573).

- Particle Counter PC 400 – Stationary Solution in combination with DS 400 (Recorder) is suitable for:

✓ air / compressed air ✓ argon (Ar)

✓ nitrogen (N2) ✓ oxygen (O2)

- Particle Counter PC 400 – Mobile Solution in combination with DS 500 Mobile (Recorder) is suitable for:

✓ air / compressed air ✓ argon (Ar)

✓ nitrogen (N2) ✓ oxygen (O2)

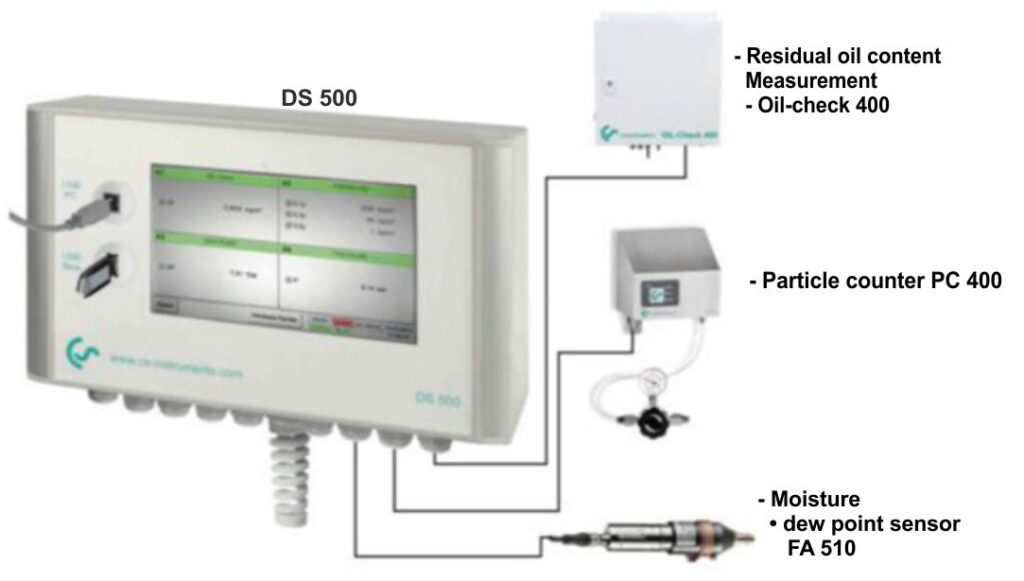

COMPRESSED AIR QUALITY MEASUREMENT – Residual Oil Content Measurement OILCHECK in combination with Particle Counter PC 400 according to ISO 8573.

- Mobile Solution – Residual Oil Content Measurement OILCHECK in combination with PC 400 Particle Counter + DS 500 Mobile + FA 510 Dew Point Sensor + CS Basic – data evaluation in graphic and table form.

- Stationary Solution – Residual Oil Content Measurement OILCHECK in combination with PC 400 Particle Counter + DS 500 + FA 510 Dew Point Sensor + CS Basic – data evaluation in graphic and table form.

RECORDERS.

For all related compressed air and gas measurements and controls.

- Stationery Recorders – DS 400 – Chart Recorder

- Stationery Recorders – DS 500 – Intelligent Chart Recorder

- Portable and Mobile Recorders – PI 500

- Portable and Mobile Recorders – DS 400 mobile

- Portable and Mobile Recorders – DS 500 Mobile – Intelligent Mobile Chart Recorder

- Portable and Mobile Recorders – DS 500 PM Mobile – efficiency measurement for compressors

SOFTWARES – CS Basic

- CS Basic – 0554 8040

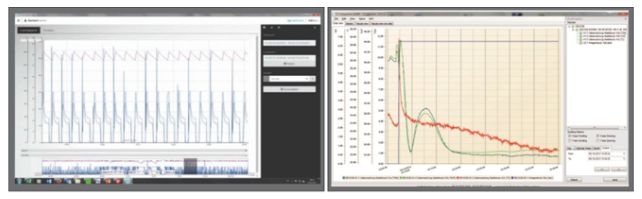

Data evaluation in graphic and table form – reading out of the measured data via USB stick or Ethernet. License for two working stations.

- CS Soft Basic – 0554 7040

Data evaluation in 5 languages by means of CS Soft Basic. Everything at a glance: Table, graphic, statistics – at the touch of a button the user gets all necessary information.

SOFTWARES – CS Soft Network & Energy Analyzer

- CS Soft Network

By means of the CS Soft Network an optional number of DS 500 or DS 400 instruments can be evaluated via Ethernet. The software stores the measured data of all instruments cyclically in a SQL database on the server.

- CS Soft Energy Analyzer

Serves for compressor analysis, system analysis or leakage calculation. Evaluation at the PC with graphics and statistics. Graphic evaluation with day view and week view. Compressed air costs in €/$.

SOFTWARES – CS Service Software

- CS Service Software – VA 5xx

The service Software for our flow sensors enables the user e.g. to scale the 4…20 mA analogue output range or to change other parameters of the device.

- CS Service Software – FA 5xx

Very useful for connecting the humidity sensors to the PC and the following adjustments can be carried out, for e.g.: Scaling of the 4…20 mA analogue output, alarm limits, single-point calibration.

POWER METERS

- Mobile active/reactive power meter CS PM 600

with 3 external current transformers for big machines and plants. Measures kW, kWh, cos, phi, kVar, kVA.

- CS PM 5110 Current/effective power meter

for panel mounting. Current transformer up to 2000 A connectable.

- Clamp-on ammeter Miniflex

Measuring ranges of the clamp-on ammeter: 0 – 400 A. For the analysis of compressors.